3D Printing: History, Types, and Materials

3D printing has come a long way since the technology was first invented in the early 1980s. Today, there are several uses for 3D printing, from life-saving medical procedures to rapid prototyping to solutions for global warming. As the technology matures, so do the materials needed for 3D printing. ACI Materials provides inks and materials that help build 3D-printed electronics and more.

What is 3D Printing?

3D printing is the process in which a three-dimensional object is created layer by layer using a printer and CAD software. The software program creates a digital model of the finished object and tells the printer how much material to deposit and where.

3D printing was invented in the early 1980s in Japan as a means to produce prototypes rapidly. 3D printing is not only a fast-growing hobby, but it also has life-saving applications. In 2015, a young American boy was the first to receive a 3D-printed prosthetic after recovering from a traumatic accident. Now, 3D printers make excellent holiday gifts that can be bought with just a few clicks on Amazon.

Depending on the types of materials used for 3D printing, the process can also help solve ecological problems. 3D printing can use recycled plastic materials and also help speed up the prototyping process, which leads to less manufacturing waste.

3D Printing and Additive Manufacturing

3D printing sometimes goes by other names including rapid prototyping and additive manufacturing. 3D printing is a form of additive manufacturing.

Additive manufacturing is the creation of objects by adding materials. This is the opposite of subtractive manufacturing, which creates objects by removing materials. Subtractive manufacturing typically creates more environmental waste and harmful chemicals. Additive manufacturing is considered an environmentally friendly process.

Types of 3D Printing and Typical Materials

The type of material you choose will depend on what type of 3D printing process you are using. There are three main types of 3D printing:

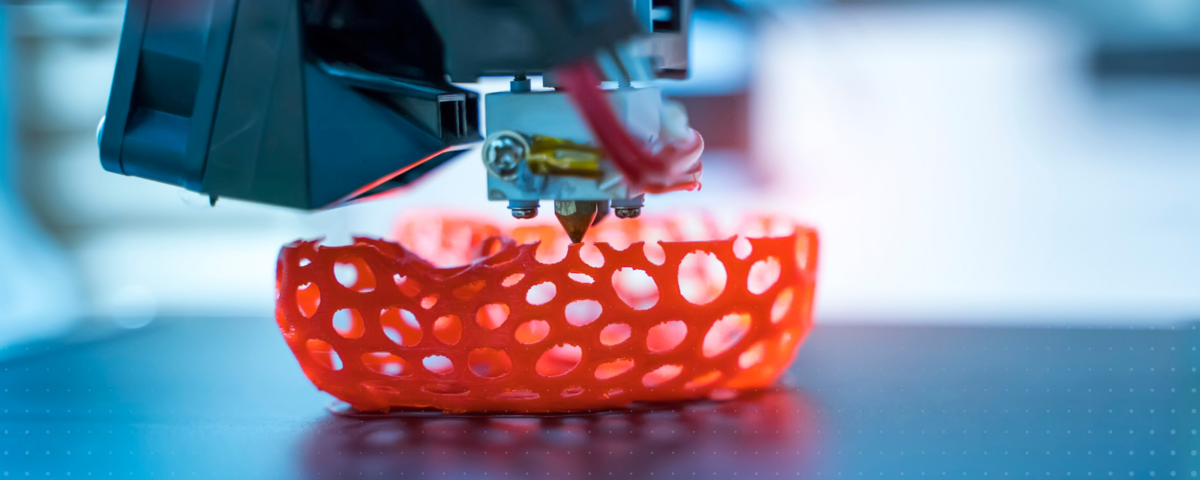

- Fused deposition modeling (FDM) – material is melted and printed through a nozzle that deposits the material layer by layer. This is the most common type of printing among hobbyists today.

- Stereolithography (SLA) – a laser cures liquid materials into hardened plastics using a process called photopolymerization. This process was the original 3D printing process invented in the 1980s.

- Selective laser sintering (SLS) – a high-powered laser fuses small particles of materials together. This process is typically used in manufacturing to produce strong, sturdy parts.

Most 3D printers use plastic or polymer materials, but FDM printers can also support metals, alloys, and ceramics. SLA printers use various resin materials and SLS printers use nylons or TPU material.

Benefits of Alchemy Conductive Inks in 3D Printing

Alchemy conductive inks are proprietary hybrid ink designed by ACI Materials. Alchemy conductive inks are a semi-sinterable ink that offers the ease of use and the curing and process time of a polymer thick film but with the electrical conductivity of sinterable inks.

In a 3D printing environment, alchemy conductive inks can be extruded through a nozzle to print finer features on printed electronics. Alchemy conductive inks have less slump compared to traditional inks which makes it easier to print finer traces and spaces. These inks can also be used for lower-temperature 3D-printed parts. Conductive inks also reduce prototyping times by allowing a printer to produce parts rapidly because of the faster cure times of the inks.

In a 3D printing environment, alchemy conductive inks can be extruded through a nozzle to print finer features on printed electronics. Alchemy conductive inks have less slump compared to traditional inks which makes it easier to print finer traces and spaces. These inks can also be used for lower-temperature 3D-printed parts. Conductive inks also reduce prototyping times by allowing a printer to produce parts rapidly because of the faster cure times of the inks.

NScrypt used alchemy conductive inks during the 3D printing process to create a fully functional cylindrical acoustic sensor platform equipped with Bluetooth communication. By 3D printing circuits, it allows for more volumetric savings in areas where traditional printed circuit boards fall flat.

Contact ACI For Your Material Needs

ACI Materials is the trusted partner of several functional printers. Contact us to learn more about conductive inks and get started on your next 3D-printed electronics project.